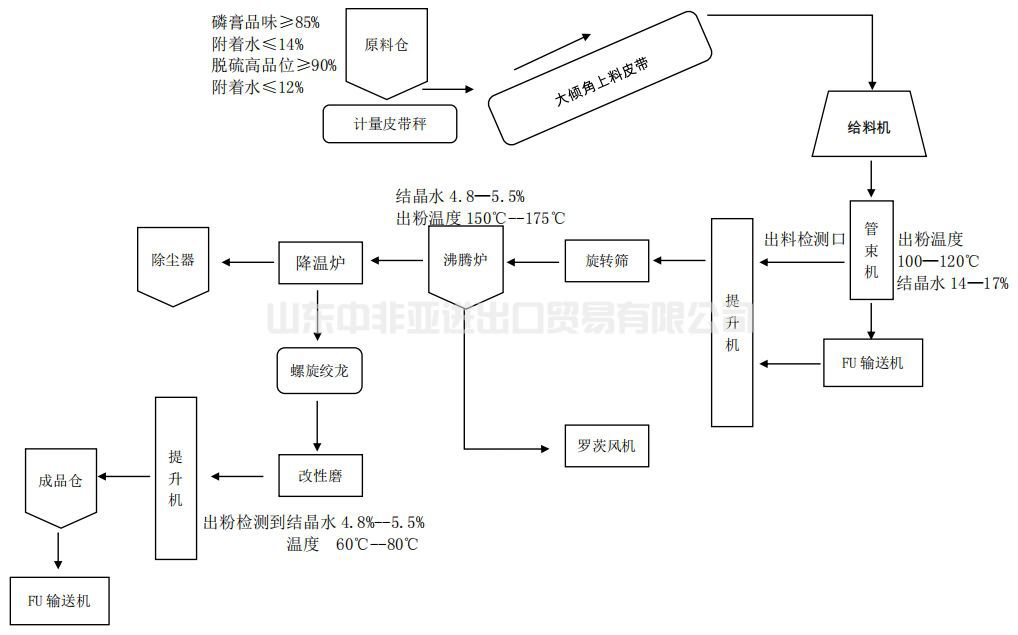

The calcination line of our company adopts the two-step method of pre-drying the surface water in a tubular dryer and calcination of crystal water in a boiling furnace. After calcination, the gypsum p

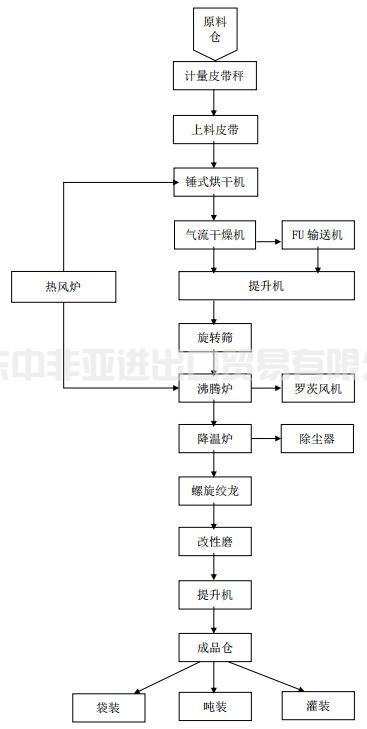

This process uses hammer dryer and air dryer as pre-drying surface water, boiling calcining furnace calcining crystal water two-step calcining method, gypsum powder calcining after cooling furnace coo

The modified mill is suitable for changing the crystal structure of gypsum powder. Increase the strength of gypsum powder. The modified mill is divided into needle mill and ball mill.The ball mill is

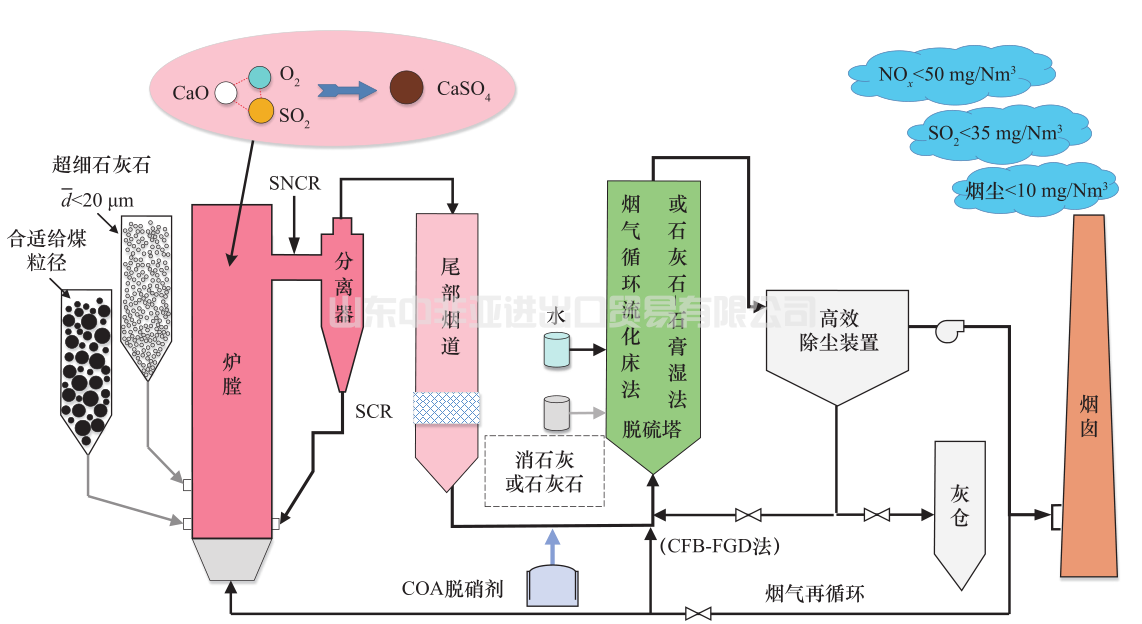

Desulfurization and denitrification are the processes of acid-base neutralization. Desulfurization is the removal of SO2(sulfur dioxide) from the flue gas, and de-stocking is mainly the removal of NOx

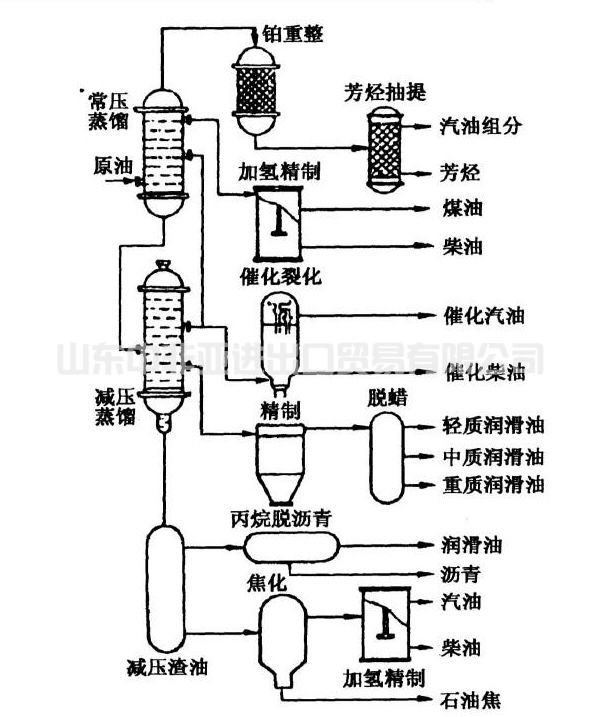

Petroleum equipment process refers to the process of converting crude oil into various petroleum products, including separation, conversion, upgrading and manufacturing. The specific process flow is a

1.desulfurization process introduction:There are many flue gas desulfurization processes, which can be roughly divided into three categories: wet method, semi-dry method and dry method. According to w

On July 25, 2022, the first construction gypsum powder production line of Datang Sanmenxia construction gypsum powder production line with an annual output of 100,000 tons was successfully tested by D