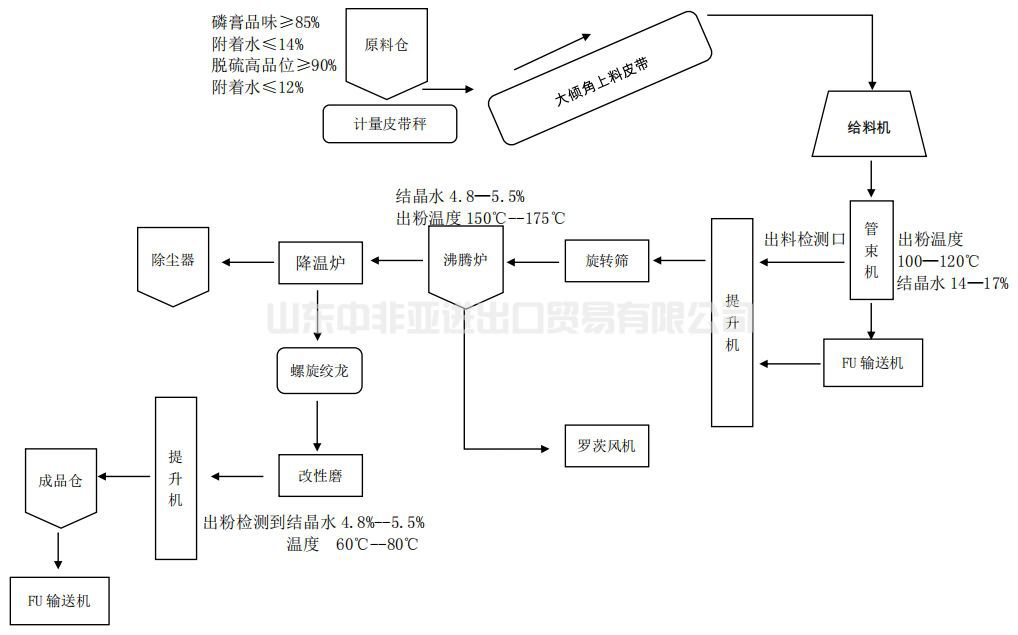

The calcination line of our company adopts the two-step method of pre-drying the surface water in a tubular dryer and calcination of crystal water in a boiling furnace. After calcination, the gypsum powder is cooled by a cooling furnace (the temperature is about 60-80℃), and then modified by a modified grinding powder, and then homogenized and packaged. The detailed process is described as follows:

1. The raw materials are sent from the feedstock yard to the upper hopper by the loader. A heavy quantitative belt scale (stable, accurate and long service life) is installed at the bottom of the upper hopper. After the heavy quantitative belt scale is accurately measured, it is sent to the steam tube dryer by the belt conveyor through the impeller feeder. A permanent magnet is added to the material of the conveyor belt to remove metal impurities in the raw material to ensure the normal operation of the tube dryer and reduce the wear on its interior.

2, the raw materials into the steam tube dryer, the motor through the transmission device to drive the steam tube dryer to rotate (turn left and right), through the lifting plate installed on the outside of the steam tube tube, the material raised, in the falling process so that the material into the gap between the pipes, and fully contact the friction tube wall one by one, so that it dry; At the same time, the material is pushed forward from the feed end to the discharge port at the other end, when the steam enters from the steam joint at one end and the condensate is discharged from the steam head at the other end. The equipment shell has a thermal insulation layer (rock wool thickness is 100mm), the door cover, feed port, etc. are sealed devices, cold air is not easy to enter the machine, the heat is not easy to lose; At the same time, the condensate outlet end has a trap, which effectively avoids the ineffective escape of steam and prevents the ineffective loss of heat. The pipe dryer uses advanced steam sealing device, no steam leakage phenomenon, low heat loss, at the same time in accordance with the best energy-saving way to consider, the user can recycle the condensate water, condensate water back to the boiler system (the condensate water is soft water, no testing, no pollution), so as to form the best heat cycle process, so that the tube bundle machine heat loss reduced to the lowest point, Therefore, the tube dryer is one of the best energy-saving equipment in the drying industry.

3. After the desulfurized gypsum raw material containing surface moisture is pre-dried by the pipe dryer, a large amount of surface moisture evaporates (the remaining surface moisture is controlled within 2%), a large amount of gypsum powder is recovered by the primary cyclone dust collector after discharge, and then the residual dust is recovered by the secondary dust collection and the pulse bag dust collector. The bottom of the dust collector is equipped with FU chain conveyor. FU through the chain conveyor through the elevator into the rotary screen (sieve gypsum powder impurities), after sifting through the winch into the boiling calciner for further calcining, drying off the remaining surface water and part of the crystal water (finished β powder crystal water control at 4%-6%), calcined gypsum powder automatically overflow into the elevator. It is sent to the cooling furnace by the elevator for cooling (the temperature is reduced to about 60-80℃), and the cooled gypsum powder is sent to the modified mill for modified grinding. The ground gypsum powder enters the finished product elevator and is lifted from the elevator to the cooked powder silo. The gypsum powder enters the packaging silo (homogenizing silo) after homogenizing the finished product silo. By the packaging bin to complete the ton bag, bulk tank truck and small bag packaging in three forms.

简体中文

简体中文