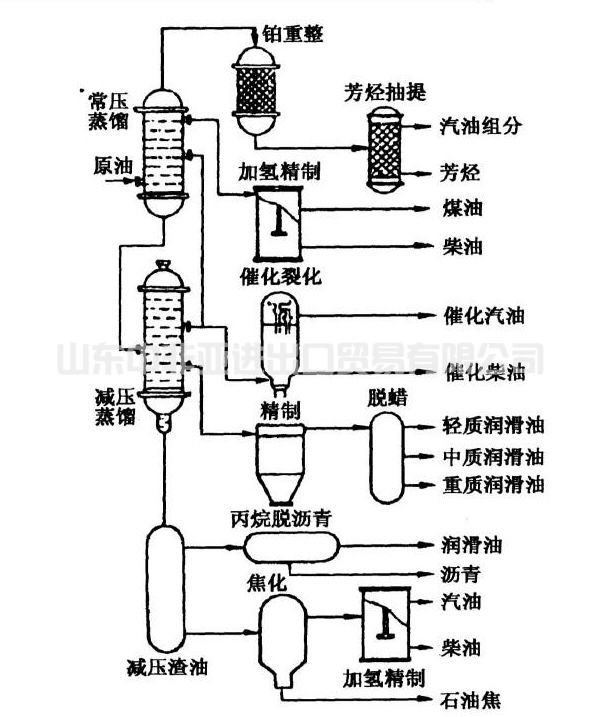

Petroleum equipment process refers to the process of converting crude oil into various petroleum products, including separation, conversion, upgrading and manufacturing. The specific process flow is as follows:

1. Crude oil processing and pretreatment

The crude oil first enters the crude oil berth from the crude oil receiving area, then goes through the steps of material dump truck cooling, centralized automatic metering, etc., and is transported to the integral heating chamber and the connected crude oil pre-separation bin.

2. Separation steps

The separation tower separates the crude oil into LPG, light naphtha, heavy naphtha, jet fuel oil, diesel oil, residual oil and other different components.

3. Transformation steps

The refinery uses catalytic cracking technology to heat the heavy raw oil and feed it into the cracking furnace, which is converted into the reactants entering the upper standpipe through the cracking process, and then further heated, cooled, filtered, and then into the storage tank for storage.

4. Upgrading steps

The upgrading step is to improve the oil by adding various catalysts and additives, etc., to improve the quality and added value of the product. Refineries also need to import some fine chemical raw materials, such as benzene, toluene, xylene and other chemicals.

5. Manufacturing steps

The manufacturing process involves the manufacture and processing of different products such as carbon black, white oil, styrene, methanol, olefins, etc., and the finished products are deeply processed, upgraded and purified. Most of them are intermediate products, which need to be further processed to produce downstream products required by users.

In short, the petroleum equipment process is the specific separation, transformation, upgrading, manufacturing process of crude oil, which needs to go through multiple processes, all links are closely linked, and any problem in any link will affect the entire production chain.

简体中文

简体中文