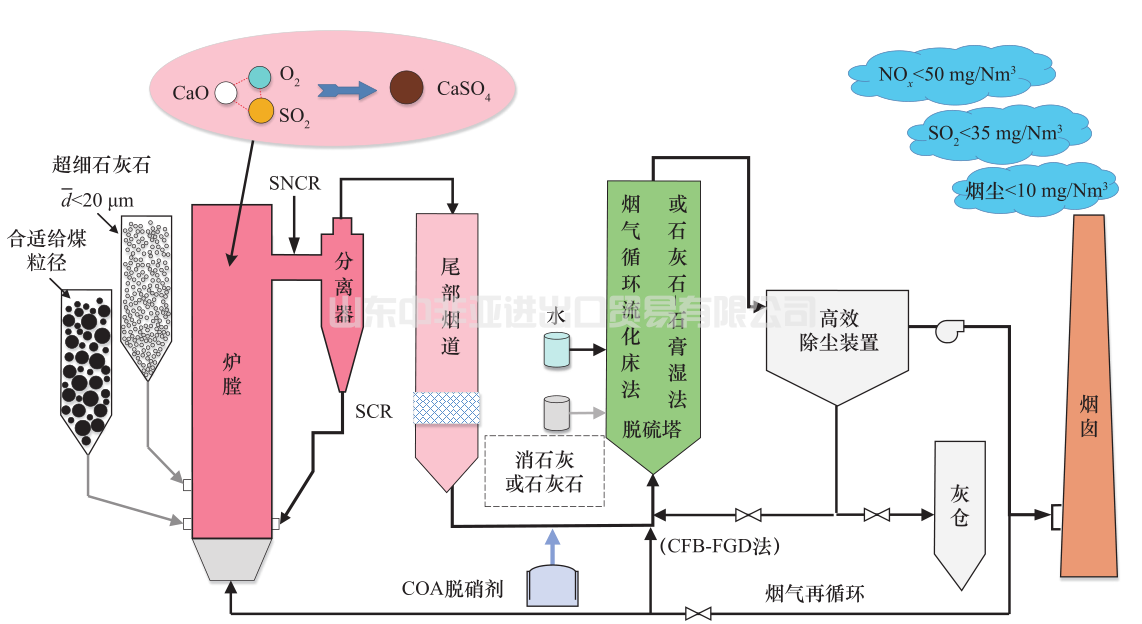

1.desulfurization process introduction:

There are many flue gas desulfurization processes, which can be roughly divided into three categories: wet method, semi-dry method and dry method. According to whether the desulfurization process adds water and the dry and wet form of the desulfurization product can be divided into dozens of types, of which the cost-effective desulfurization method is SDS dry desulfurization.

The process principle of SDS dry desulfurization is: After the flue gas enters the desulfurization reactor, the fine powder hydrogen carbonate (baking soda) is injected at the same time. Under the promotion of additives, sodium carbonate is activated by the high temperature of the flue gas, the volume increases, and the decomposition is into sodium carbonate with high reaction and strong adsorption, and the flue gas is purified.

SDS dry desulfurization is mainly suitable for gas boilers, biomass boilers, incinerators, oil furnaces, coke furnaces, ceramics and other industrial kiln waste gas treatment, without secondary gas stripping.

2. Introduction of denitrification process:

Common denitration technologies can be divided into two categories according to the formation mechanism of nitrogen oxides:

1, front-end treatment, control the formation of NOx in calcination; The general methods are: ① use low nitrogen burner; ②The combustion temperature in the decomposition furnace and the pipeline, reduce the combustion temperature, etc.;

2, end treatment, control of flue gas NOx emissions, the general methods are: ① selective non-catalytic reduction method (SNCR); ② Selective catalytic reduction (SCR); ③PNCR polymer denitration.

Denitrification process principle: dry powder denitrification agent is sprayed into the furnace, and amino groups react with nitrogen oxides at high temperatures to remove nitrogen oxides. Denitration efficiency up to 90%, no secondary pollution, no ammonia escape safety risk, small footprint, boiler and flue no pressure loss. Denitrification agent also has a flame retardant function, which can improve the thermal efficiency of the boiler. Compared to SCR, the investment operation saves two thirds, with no additional operating maintenance costs.

The denitrification process is mainly applicable to cement plants, power plants, biomass boilers and other boilers and most kilns, so that NOX meets the emission standard, and the polymer carbon skeleton is naturally decomposed into carbon dioxide release.

简体中文

简体中文