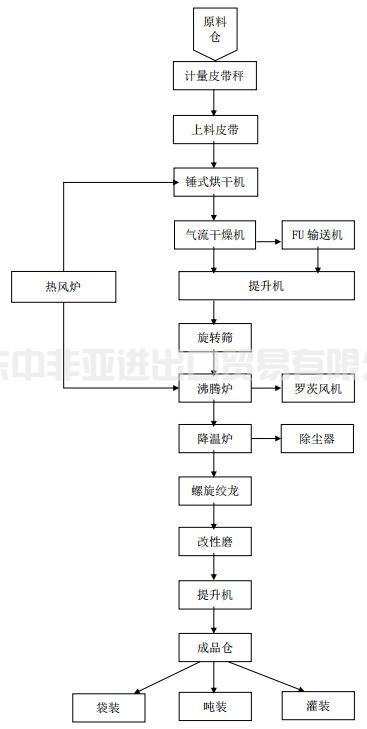

This process uses hammer dryer and air dryer as pre-drying surface water, boiling calcining furnace calcining crystal water two-step calcining method, gypsum powder calcining after cooling furnace cooling (temperature 60-80℃ or so), after needle grinding modification, homogenized packaging, detailed process is described as follows:

1, through the loader to the raw materials from the raw material yard to the upper hopper, the bottom of the hopper installed a heavy quantitative belt scale (its stable, accurate measurement, long service life), after the heavy quantitative belt weight accurate measurement by the belt conveyor through the impeller feeder into the hammer dryer, in the conveyor belt conveyor material add a permanent magnet to remove metal impurities in the raw materials, To ensure the normal operation of the hammer dryer and reduce its wear.

2, the hammer dryer is divided into gypsum powder inlet, hot flue gas inlet, hammer rotor, inner cavity, outer shell, mixing outlet, starting motor, starting cabinet and other 9 parts, its structure is also divided into the inlet and outlet for a trouser form, the inlet adopts the top feed, the side into 600 degrees of hot flue gas, raw materials and hot flue gas mixed into the hammer dryer chamber. After crushing, dispersing, lifting, drying, etc., the surface water is removed into the discharge port, and the wet material and block material that are not dried are returned to the chamber of the hammer dryer to continue crushing, dispersing, lifting and drying. Then it goes to the pulse air dryer for re-dehydration.

3. The desulfurized gypsum raw material containing surface moisture is pre-dried by the hammer dryer, and a large amount of surface moisture evaporates (the remaining surface moisture is controlled within 2%). After discharge, a large amount of gypsum powder is recovered by the primary cyclone dust collector, and then the residual dust is recovered by the secondary dust collection and the pulse bag dust collector. FU through the chain conveyor through the elevator into the rotary screen (sieve gypsum powder impurities), after sifting through the winch into the boiling calciner for further calcining, drying off the remaining surface water and part of the crystal water (finished β powder crystal water control at 4%-6%), calcined gypsum powder automatically overflow into the elevator. After being sent to the cooling furnace by the elevator for cooling (the temperature drops to about 60-80℃), the cooled gypsum powder is sent to the needle mill for modified grinding, and the specific surface area of the gypsum powder is controlled to 4800-6500mg/cm. The ground gypsum powder enters the finished elevator and is lifted from the elevator to the cooked powder silo. Gypsum powder is homogenized in the finished silo into the packaging silo (homogenization silo), and the packaging silo completes the three forms of ton bag, bulk tanker and small bag packaging.

4. In order to achieve the production of qualified gypsum powder and the stability of product quality, it is mainly to control the temperature of powder production, and the method of supplying low temperature air is adopted to control the temperature. The source of low temperature air is borrowed from the discharge air volume of the boiling calciner, and the discharge temperature is about 150-180 degrees, which is also a process of coal saving. The air supply of the hot blast furnace also uses the air volume and temperature here. An adjusting butterfly valve is installed in the middle of the air supply pipe. According to the actual use temperature, the electric actuator is used to control the size of the air supply volume to adjust the required temperature, which can achieve automatic adjustment.

简体中文

简体中文