Calcium silicate board as a new green building materials, in addition to the functions of traditional gypsum board, but also has superior fire performance and moisture resistance, long service life ad

Calcium silicate board plasterboard1.gypsum board is made of gypsum, the surface is a special

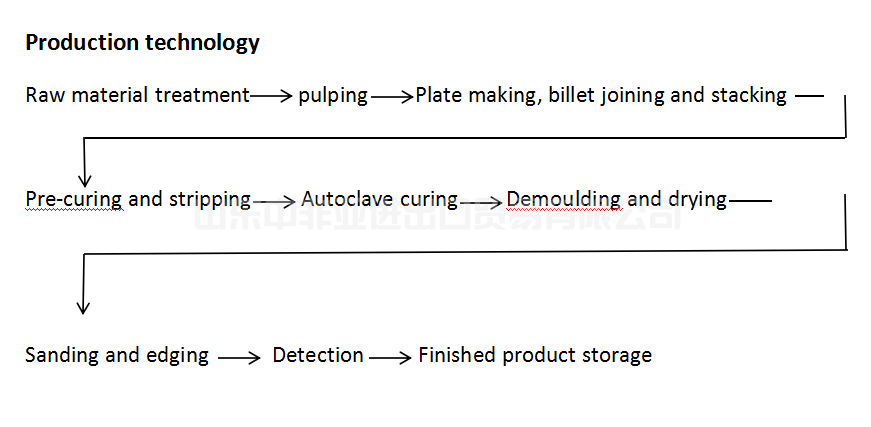

The production process of calcium silicate board includes the steps of raw material preparation, mixing, pouring, curing, cutting and processing, drying, packaging and warehousing. Each step requires

Phosphogypsum is the solid waste discharged from the production of phosphate fertilizer and phosphoric acid, and about 4.5-5t phosphogypsum is produced for every 1t phosphoric acid. Phosphogypsu

The natural gypsum powder includes anhydrous gypsum and CaSO4・2H2O, if you want to commercialize the gypsum powder. you should adopt the CaSO4・2H2O, after removing part of water by

Warmly welcome Russian customers to visit our company to negotiate business

Desulphurized gypsum, also known as smoke desulphurized gypsum, sulfur gypsum or FGD gypsum, the main composition and natural gypsum, the same as calcium sulfate dihydrate CaSO4 · H2O, content 93%. De

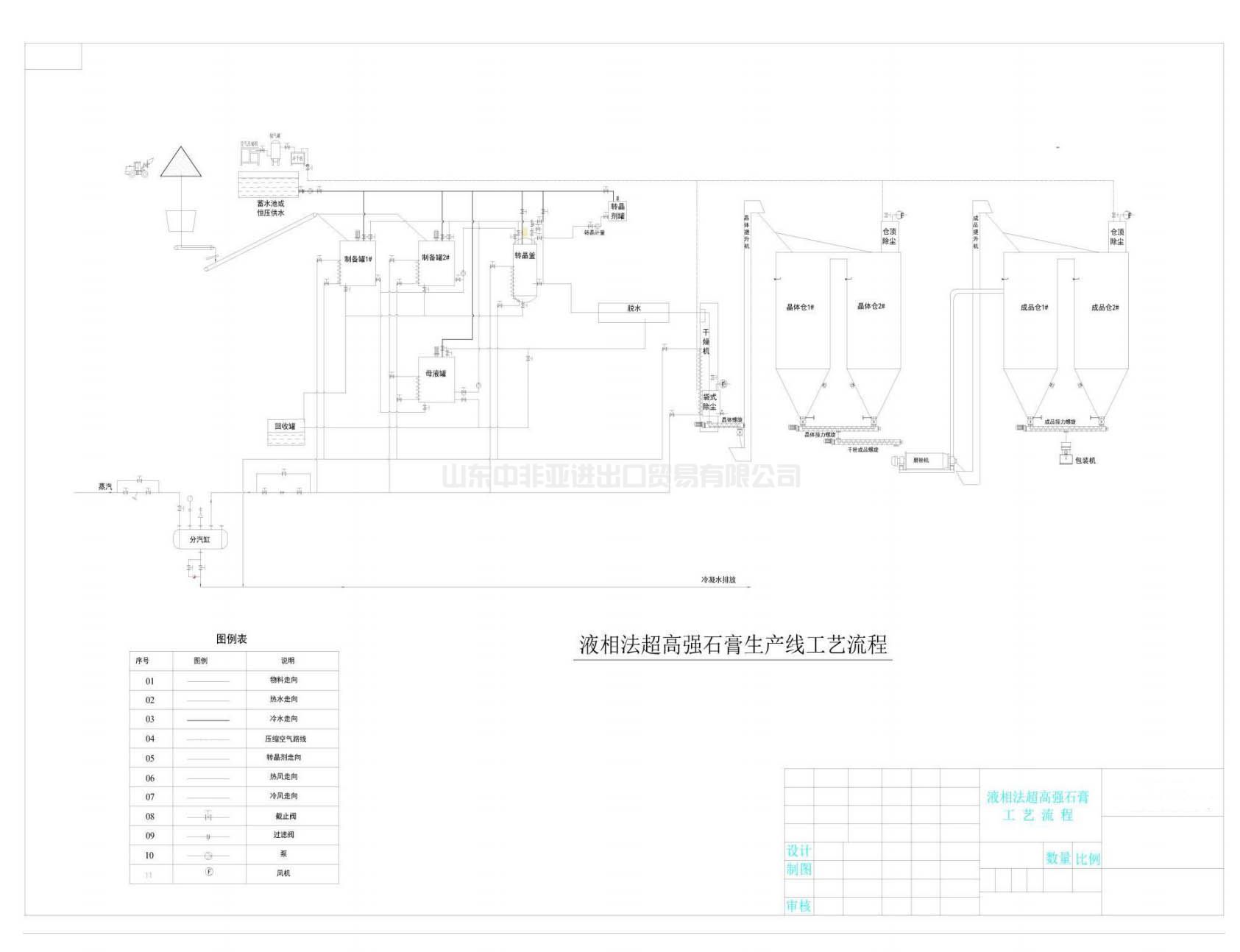

1、Production process flow of ultra-high strength gypsum (steam heating+chemical gypsum raw materials)2、Process IntroductionRaw material preparation:The gypsum powder raw material with a grade of over

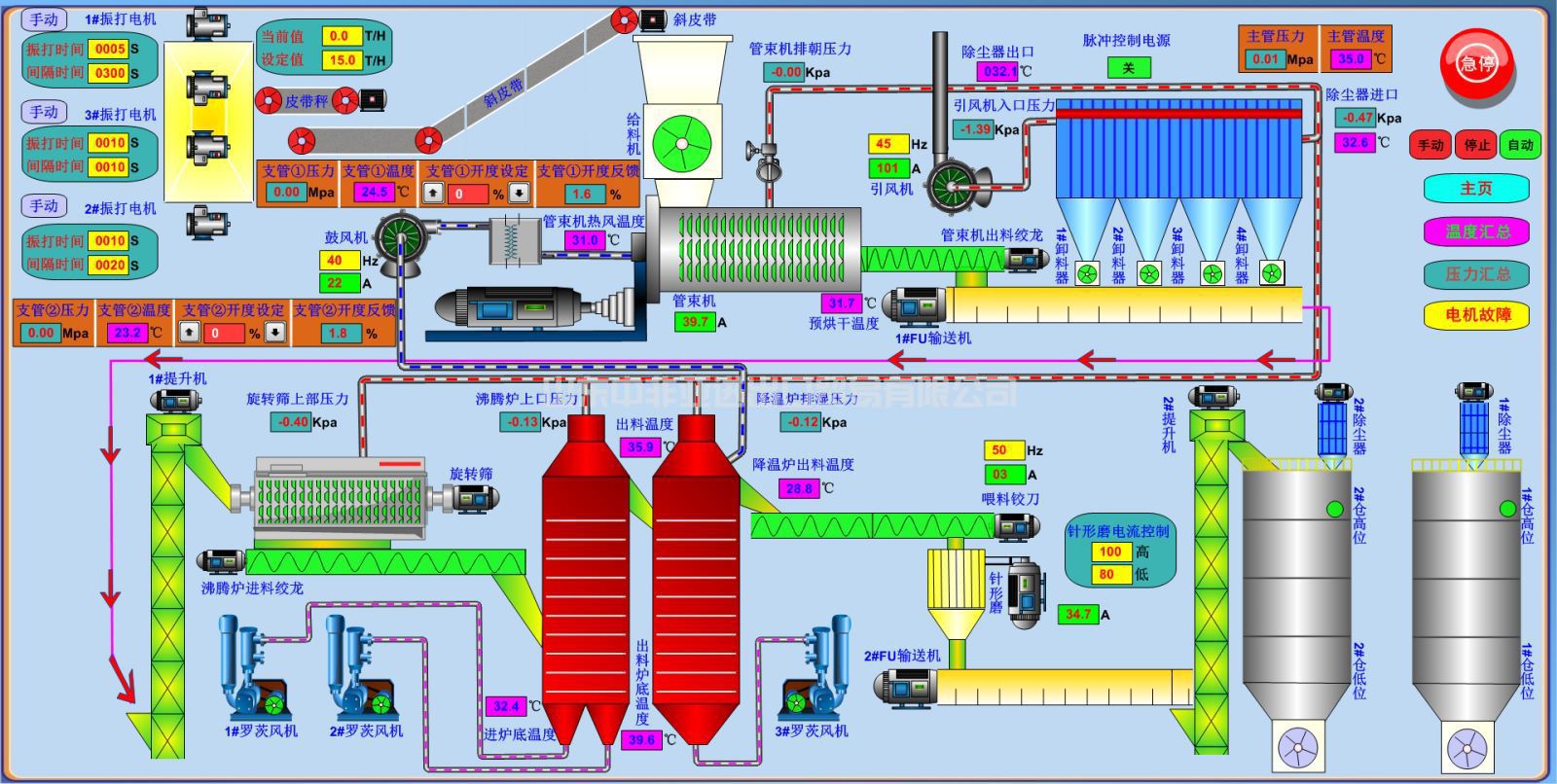

The electrical control system adopts the current advanced DCS (distributed control system), which centrally controls the equipment scattered everywhere.According to the control requirements, Siemens P

The exquisite PLC cabinet is the external image of the whole PLC control system, which is not only economical, but also high-end, atmospheric and high-grade, but also takes into account the requiremen