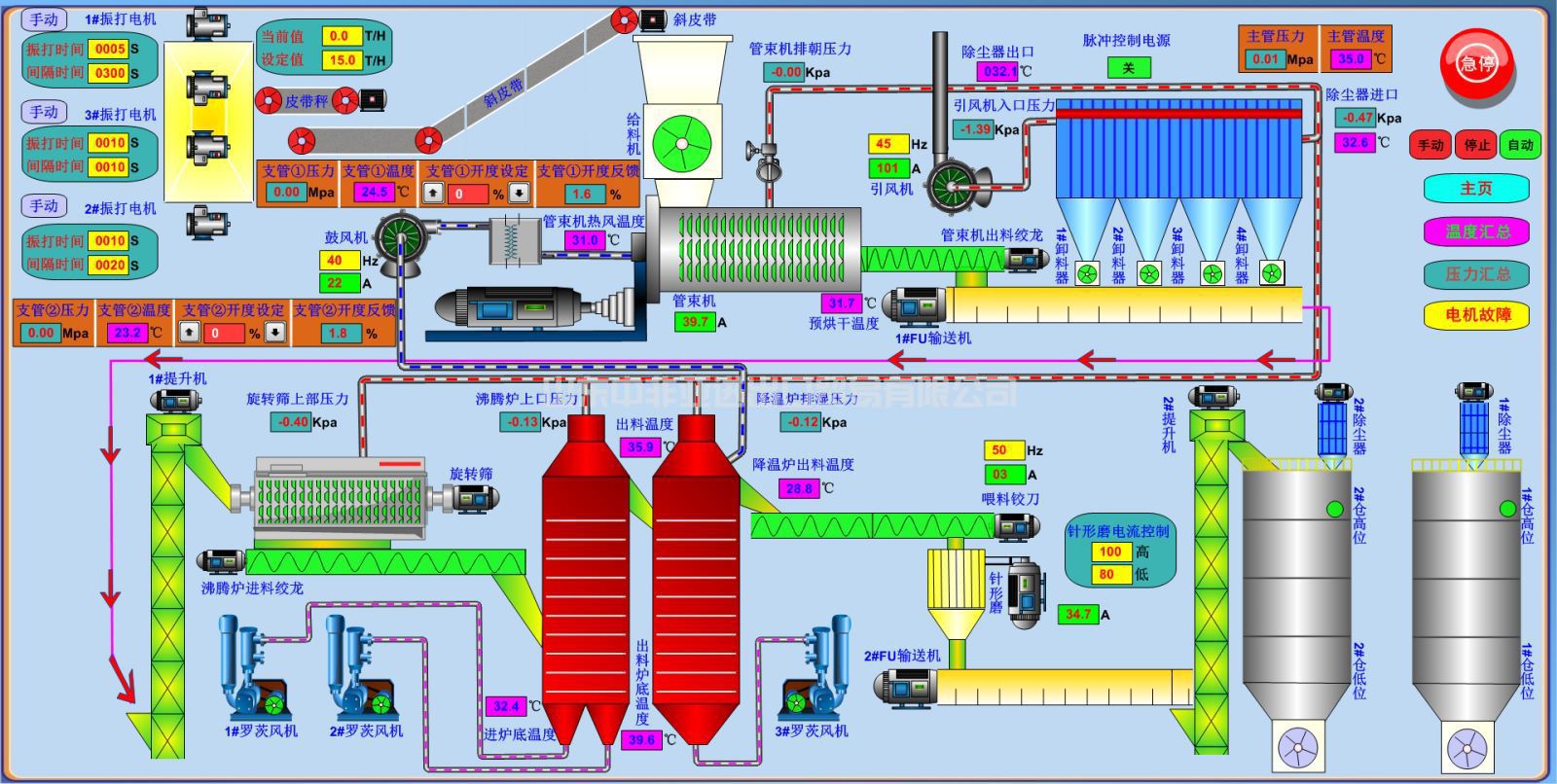

The electrical control system adopts the current advanced DCS (distributed control system), which centrally controls the equipment scattered everywhere.

According to the control requirements, Siemens PLC, industrial control computer and industrial configuration software (Kingview) are used as the core parts of alarm, monitoring and electrical control, and each single device is logically controlled according to the process requirements, and the current, temperature and air volume of each device are uploaded to the upper computer through the data acquisition module and communication mode. After analyzing and sorting the transmitted parameters, the upper computer displays and alarms the abnormal conditions such as overcurrent, overload, overtemperature and low temperature.

The communication module uploates the analog signals of calcining kiln import oil temperature, feed powder temperature, export oil temperature, export powder temperature and furnace temperature to the host computer through 485 communication mode. The temperature and air volume of each part and the operation process of the whole production line are monitored on the upper computer. According to the crystal water content of the produced powder, the amount of powder in the calcining kiln can be adjusted on the upper computer. When the crystal water content is high, the frequency of the feed belt conveyor converter can be reduced. When the crystal water content is low, increase the frequency of the feed belt inverter.

The data acquisition module collects the current data of high-power equipment such as mill, exhaust fan and induced draft fan and uploits it to PLC. Through the data exchange between PLC and the host computer, the current change of the above equipment can be monitored on the host computer. When there is overcurrent, overload, phase deficiency, short circuit, etc., the alarm indicator flashes to send an alarm and delay the shutdown.

The upper configuration software sets the function of data report, which can reflect the data and status in the production process, and record the data. It can not only reflect the real-time production of the production line, but also carry out statistics and analysis of the long-term production process, so that the production staff can grasp and analyze the production situation in real time, and can make real-time reports and historical reports. Real-time reports and historical reports can be analyzed and printed.

简体中文

简体中文