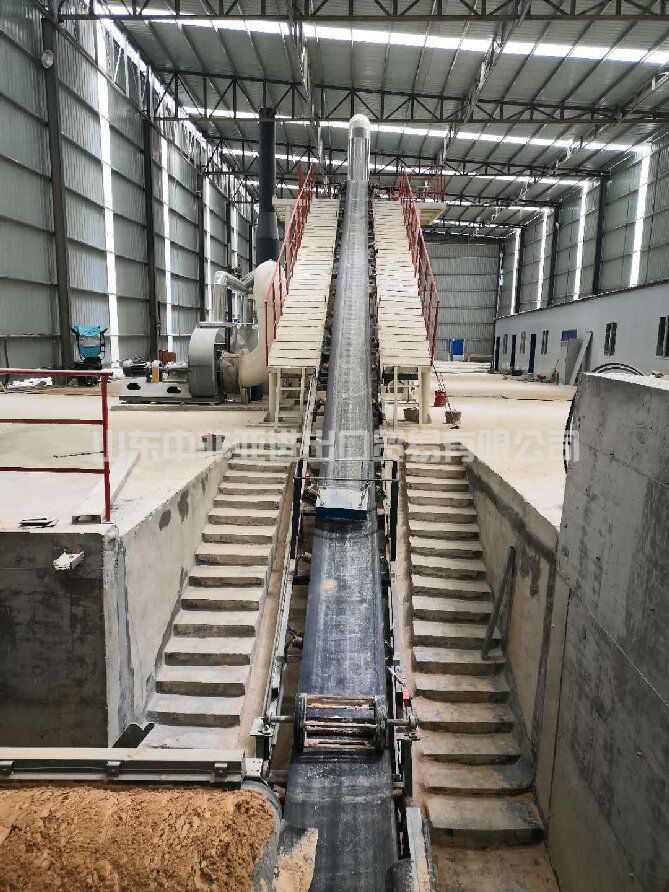

The raw materials are sent from the feedstock yard to the upper hopper, and a heavy quantitative belt scale (stable, accurate and long service life) is installed at the bottom of the upper hopper. After the heavy quantitative belt scale is accurately measured, the belt conveyor is sent to the steam tube dryer through the impeller feeder. A permanent magnet is added to the material of the conveyor belt to remove metal impurities in the raw materials. To ensure the normal operation of the tube dryer and reduce its wear.

简体中文

简体中文