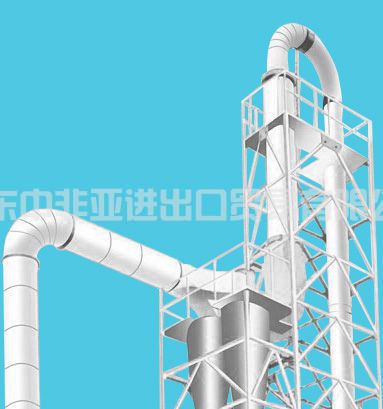

After the air is filtered and heated, the temperature reaches 80 ~ 300℃(adjustable). The material is added to the hopper, and is uniformly added to the drying pipe by the screw feeder to contact with the hot air and flow, forming a complex heat exchange process dominated by convection, and finally meet the drying requirements of the product. Through the gas-solid mixture after the drying pipe, the material is recovered by the cyclone separator, and then the powder is separated by the bag dust collector (the recovery rate below 500 mesh can reach 99%), and the exhaust gas is drained by the induced draft fan.

Advantages:

1. High drying strength, high thermal efficiency, large processing capacity;

2. Short drying time, suitable for heat-sensitive materials;

3. The material has less contact with the outside world, is not polluted, and the product quality is good;

4. Simple structure, small size, easy to operate.

简体中文

简体中文