CNC multilateral plate bevelling machine is a processing line which it can process the plate edge up and down side bevel in one time feeding. Bevelling type for 1、V、K U and transition bevel. Processing thickness range from 4mm to 300mm .The plate bevelling machine comprises of 4 models :1.Unilateral plate bevelling machine 2. Bilateral plate bevelling machine 3.Trilateral plate bevelling machine 4.Quadrilateral plate bevelling machine. Those machine is widely used in steel bridge, container, steel structure,engineering machinery, shipbuilding. wind power, nuclear power, boilers etc.

CNC Multilateral Plate Bevelling Machine advantage :

l Processing high efficiency (more than edge milling machine, chamfering machine 12times)

1)The max plate feeding speed can get 8m/min

2) One time feeding can finish plate edge of up and down bevel and blunt the edge of the synchronous processing

l High machining precision

1) Processing straightness accuracy≤0.5mm/10000mm

2) Processing width accuracy≤0.5mm

3) Bevel surface roughness Ras12.5um

l High automation

In the process of centring, positioning, feeding, bevel angle adjustment, cutting accuracy control,host lock,heat dissipation chip removal,material discharging, and all are realized automation control

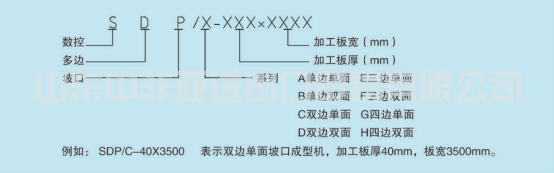

The specifications representing method

Product innovations

l Unique technology, leading technology

Our machine adopts the combination of pneumatic ,component elastic ,follow-up testing .more partialpress of the new process,also Solve the technical problems .

l Special cutting tools and high speed cutting

We adopt the multi knife teeth and receive the minimum knife shock point, Absorbing the foreign advanced design features of milling cutter and use the special cutting blade , and we reached the overloading of high speed cutting technology and technical requirements , and we changed the traditional model of processing.

l Bilateral plate synchronous, one time processing

Tool cutting have the parallel displacement function and up and down movement fucntion, and it can be processed 1, V. X. U bevel form, to change the traditional equipment cutting way and improve the effect. and get the one time bevel and received the standard of roughness and straightness for metal cutting.

l No need pinch and auto feeding

After the metal plate feeding,automatically centering ,automatically feed, metal plate surfacing with automatic clamping device, within 1 ~2 minutes to complete the automatic alignment and clamping action.

l Automatic chip removal,air cooling

The application of followup self-adjustment seal cutting method , the beveling and chamfering edge both running at sometime, and the chips is concentrated into the junk box to improve working conditions. With the air cooling reduces the cutting of the red edge degree and prolong the knife service life in enhancing the host machine stability and reliability

l Compact structure, separation of freely

This equipment is reasonable layout and make full use of space structure,According to the need of maintenance, it can be automatically separated and closed at any time ,when the machine working also two box body is one body for quickly changed the tool create a space adequately.

l High-speed precision, safety and reliablity

The equipment working speed is according to different specifications, different models of plate and feed speed. The machine running adopts digital detection and signal feedback system, when overload or an accident, the system will automatic outage protection.

The selection of main structure

l The cutter disc (for plate thickness ≤50mm , less bevel angle)

The structure can process bevel type : l、V.K .The bevel angle changes need to change the angle of the corresponding cutter. The machine composed by right and left host machine, each host is 3 independent drive milling unit separately finished the up down bevel and truncated edge. The machine compact structure, less control points, self-developed CNC system, high cost performance.

l The bevel angle can be adjusted automatically (plate thickness>30mm U type bevel can be done)

This machine can be realized in 0 -45° Angle adjustment automatically, without need to change the knife dish, it can satisfy the processing of different bevel angles, and it also can be realized U bevel . The machine composes of right and left host machine, each host is 3 independent drive milling unit separately finished the up down bevel and truncated edge. It is has 0- 45°angle adjustment function, lift up and down function .level feed cutter function. The structure is complex and more control points, and it is self-developed CNC system and high-level automation.

简体中文

简体中文